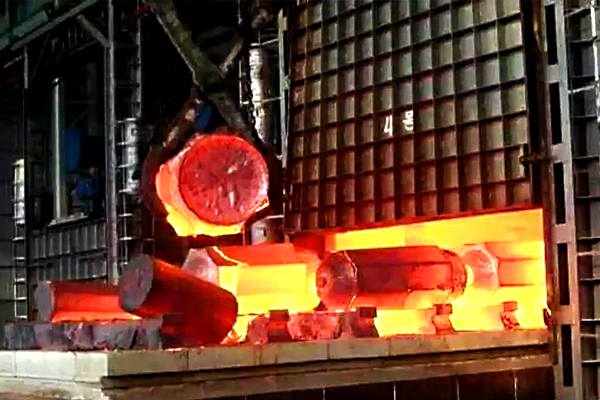

The heat treatment process of steel is a hot working process. The structural structure of the steel is changed by heating, heat preservation and cooling, so as to achieve the required performance of the workpiece.The advantage of heat treatment is that it can improve the mechanical properties of the material, reduce the weight of the structure, and improve the quality of mechanical products, thereby greatly extending the service life of machine parts.

Medium carbon steel is an iron-carbon alloy material with a carbon content of 0.0218%-2.11%. The medium carbon steel should be pre-heated before the final heat treatment to obtain a uniform pearlite and ferrite structure, which can reduce the inhomogeneity of the structure in the steel and prepare the structure for the final heat treatment.

The final heat treatment methods of medium carbon steel include quenching and tempering, low temperature tempering after quenching, low temperature tempering after high frequency quenching, isothermal quenching and medium temperature tempering after quenching.

Quenching and tempering. The organization is tempered sorbite. This structure has good comprehensive mechanical properties, high strength, good plasticity and toughness. The quenched and tempered steel should have good hardenability to ensure uniform structure and performance on the entire section of the quenched and tempered part. After quenching and tempering, medium carbon steel is mainly used to make various drive shafts, connecting rods, clutches, shaft pins, bolts, etc.